Bearing Repack 101

Published on Mar 13, 2019

Many of us who love to camp know that our RVs require maintenance. We know that fridges can stop working, propane tanks need to be filled, batteries charged, etc. We may hear of many things that “need to be done”, but sometimes it feels like trying to speak another language. Unless we know WHY we should be doing something, it simply isn't on our radar. We just know we want to get out on the road and arrive at the campground safely so that we can begin our holiday.

One item worth drawing attention to however is Wheel Bearing Repacks. Sounds like a foreign language?! That’s ok, read on, we can help with that!

Bearing Repack 101

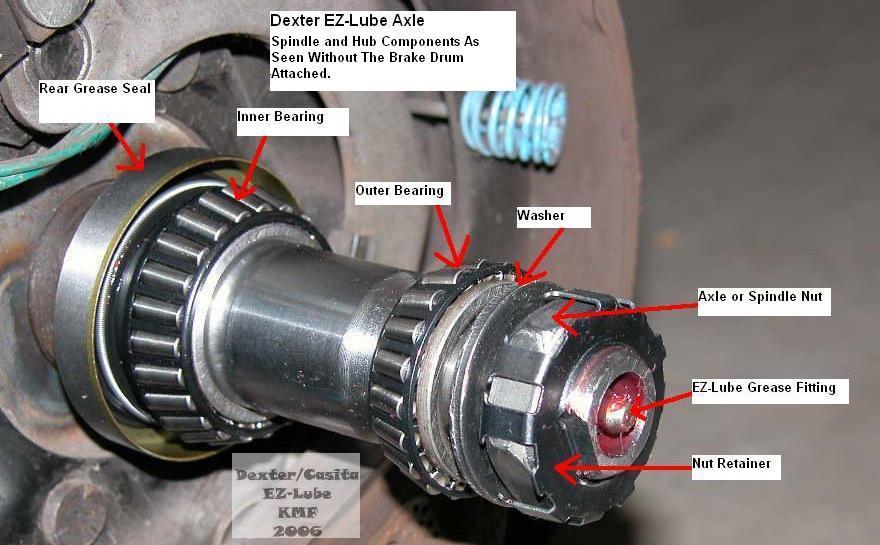

What is a bearing first of all. Most of us may have a general idea but basically they allow the wheel to turn uninhibited on the axle. They help make your trailer “go” in other words! When the bearings are properly “packed” with grease, they are allowed to spin freely without causing friction.

.jpg)

Image of new, clean bearings

So what happens if there is no grease or the grease is left too long unchanged. Well for similar reasons why you do oil changes on your car, if you don’t change the grease in your bearings, it can lose its protective properties. If there isn’t enough grease or its been allowed to lose its viscosity, the bearings can at this point overheat, burn or break, and inevitably fail. This would put an immediate major headache in your weekend getaway. If a failure were to happen on the highway, the wheels could become so hot you’d need immediate road side assistance, or worse case scenario, the wheel could actually come right off the trailer and you’d end up dragging it along the road. Not only would this put an end to your weekend plans, this could be financially devastating as well, not to mention dangerous.

Damage to trailer due to tire coming off the axle on the highway.

The best practice to avoid such a disaster is to have your bearings repacked annually. The benefits of taking the time for a one day appointment far outweigh the experience of a failure along the highway. Repacking allows to check for all sorts of damage including broken bearings, scoring (because sand or other dirt may have made its way inside), overheating and weakening. Why we suggest checking yearly is because there’s no real way to know if there is damage without taking everything apart. One sure sign is if after a few hours on the road, your wheel rims are hot to the touch, this is a major warning sign that something is wrong. The problem however is that you need to catch it before this point.

Examples of failed bearings

Some trailers come with a built in system for greasing your bearings. Not everybody however believes this is a perfect replacement to actually removing all the moving pieces, physically having a close up look, and manually ensuring that the grease is then repacked properly right into the bearings where it needs to go. This truly is the best way to ensure 100% peace of mind.

Another benefit to a bearing repack is that this now allows a close up view of the brakes as well since the entire hub is now removed. The brake pads, the brake magnet, etc. are all inspected at the time your bearings are repacked. Again there are no warnings that something is wrong until it goes completely wrong. The brakes on your trailer will not squeel like the brakes on your car so it is best to take an up close and personal look.

To sum it all up, you spend a lot of time planning and preparing for those few precious summer days. Whether you only get out for a couple weekends or spend months touring in your RV, the last thing you want is a bearing failure. This is just one little thing that you can do to ensure safe travels and a summer filled with amazing moments spent outdoors... not along the side of the highway!